Get Support

123-456-789-10

Customization

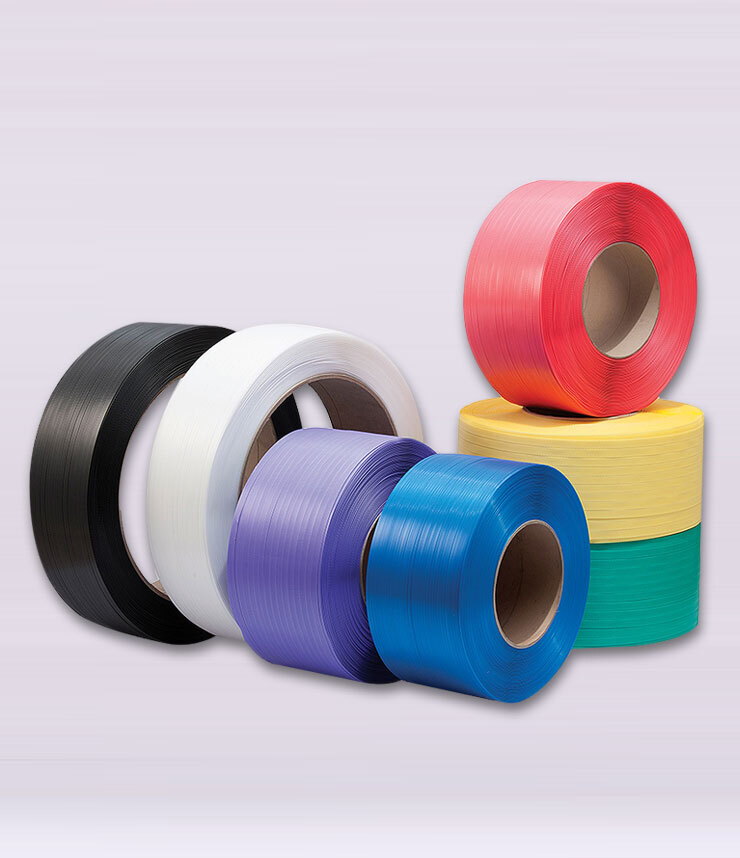

Packaging Strap Solutions, systems and products in line with the production and logistic strategies of each and every customer.

Quality

Packaging Strap Quality as a vocation, mission, vision. In every thought, gesture, product, relationship

Technology

Our focus is on state-of-the-art technology, process innovation and on heightening awareness of our products and services.

Customer first

Customer care, after sale, customer satisfaction. In Barbara they are called trust, attention reliability.

WHO WE ARE

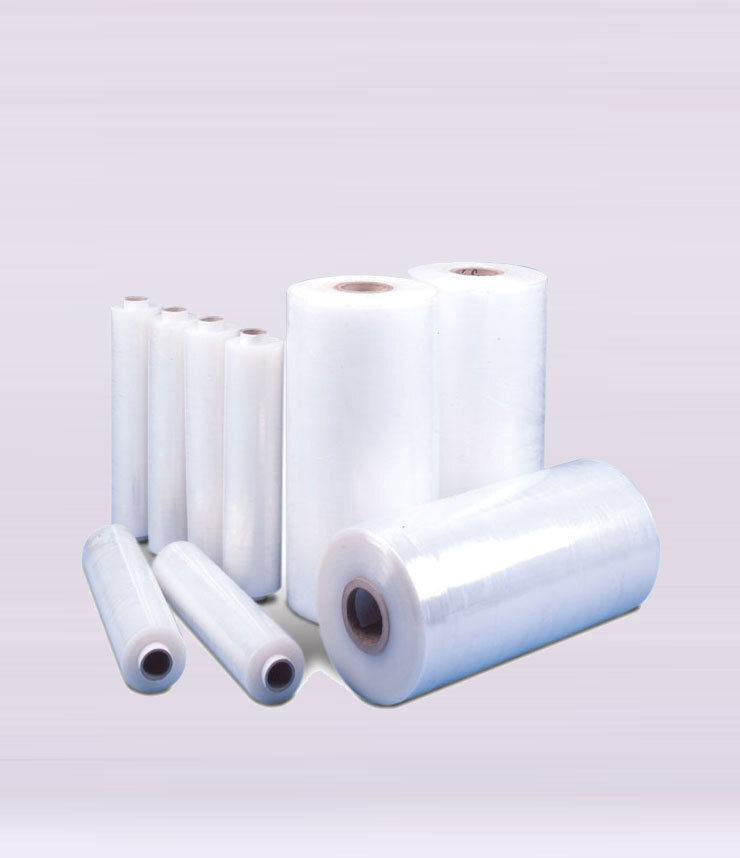

JAIRAM INTERNATIONAL PRIVATE LIMITED (formerly known as Jairam Strap Private Limited), founded in 2009, is a Leading Packaging Strap Manufacturers and Supplier & Pet Strap Exporter in India and many other continents. We offer plastic strapping solutions for a wide range of bundling and unitizing applications like Pp Strap, Composite Straps, Stretch films, etc. We have spent quality time after developing a reputation for innovation, quality, and excellent customer service for years. Our uncompromising standards have resulted in high-quality strapping regularly outperforming the competition. Based in Rajkot, Metoda GIDC, we cater entire West Coast of India, provinces of South India, and the Major North Segment. Our Product can be seen in more than 1000 Industries throughout India. We are the best Packaging Strap Suppliers in India.

Why Choose Us for Packaging Straps?

JAIRAM INTERNATIONAL PRIVATE LIMITED (formerly known as Jairam Strap Private Limited) one of the fastest-growing industries among Packaging Strap Manufacturers in India. We have achieved phenomenal growth both locally and overseas. Today, the company stands to achieve the Value of "India Global Enterprise" by the year 2036.

“JAIRAM INTERNATIONAL PRIVATE LIMITED (formerly known as Jairam Strap Private Limited)” Trusted by Millions of Industrial buyers from India as well as from around the globe, founded in 2009. We are one of the leading manufacturer, supplier and exporter of recycleable and eco-friendly PET straps, Pp Strap, Composite Straps, Polyester Straps, Stretch Films & Packaging Strap. We have spent quality time after developing a reputation for innovation, quality, and excellent customer service for years.

Quality Assurance

Big Savings

Constant R & D

Dedicated Team

Customer Satisfaction

International Network

ECO FRIENDLY

Designed for maximum added value.

- Innovative unitization techniques that maximize transportation space utilization.

- Increased safety and performance with lower energy and maintenance costs.

- The world’s largest strap recycling program to reduce waste and landfill usage.

- Manufacturing processes designed to minimize waste, pollution and energy consumption.